By developing innovative technologies and fostering a collaborative ecosystem, we aim to transform industries – from semiconductors to biotech.

This isn’t science fiction—it’s the next leap in nanomechanical engineering. And it’s happening now.

Multi-Axis Nanomechanics & Why It Matters

Imagine molecular-scale “arms” [protein structures] that can grip and move molecules in multiple directions—like tiny robotic levers, but a billion times smaller. By unlocking multi-axis control at this scale, we can:

Transform Nanoassembly

By developing innovative technologies and fostering a collaborative ecosystem, we aim to transform industries from semiconductors to biotech.

Enable High-Performance Nanomachines

From color-shifting surfaces to advanced computing components, multi-axis motion makes systems adaptive, not static.

Catalyze AI <> Nanotech

As these “nano-arms” improve, they can form physically reconfigurable circuits—potentially accelerating AI development (and vice versa).

Where we are now: Early-stage, model-driven development

We are in the Model-Based Systems Engineering (MBSE) phase, refining models, gathering data, and conducting proof-of-concept experiments to ensure precision from the start—this isn’t just theory, it’s the foundation for real-world nanomachines that will transform manufacturing, computing, and material science.

Converging Breakthroughs

Decades of research have laid the foundation. Today, four key innovations make molecular-scale assembly not just possible, but inevitable:

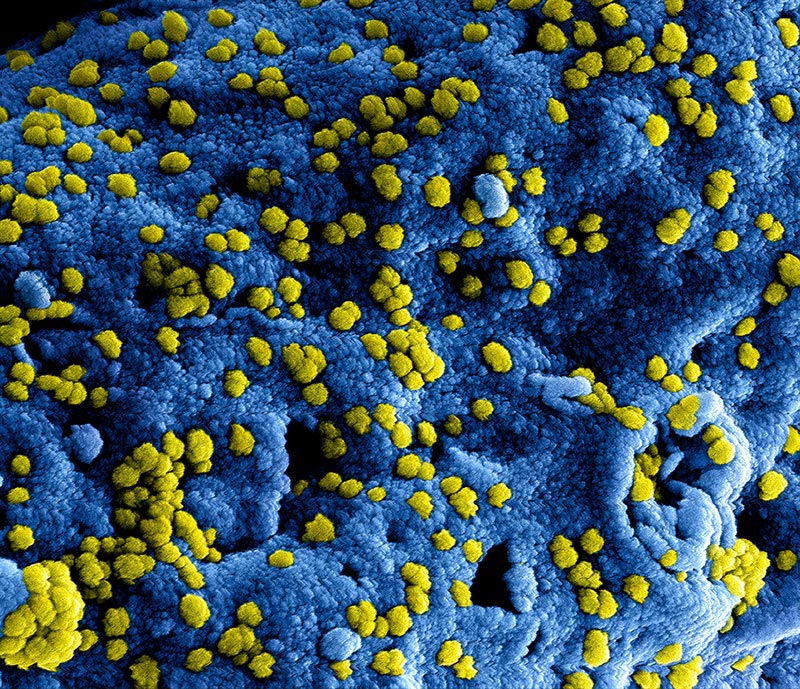

Protein Engineering

Proteins already power the biological world—enzymes catalyze reactions, molecular motors transport cargo in cells, and ribosomes assemble life itself. Now, AI-driven protein engineering is giving us the tools to design and build synthetic proteins with custom mechanical properties, transforming them into programmable nanoscale actuators.

AI models like AlphaFold and Rosetta

Custom protein "nano-levers"

Electrically responsive proteins

Advanced Sensing

Precision assembly requires real-time feedback, and until recently, our ability to monitor nanoscale movements was too slow and too blurry. That’s changing thanks to next-gen ultra-sensitive sensors and nanoscale imaging techniques.

Single-electron transistors (SETs)

Advanced atomic force microscopy (AFM) and scanning tunneling microscopy (STM)

Fluorescent and plasmonic nanosensors

AI Orchestration

Even with programmable nano-arms and precise sensing, there’s one more challenge: coordination at scale. A single molecular machine is impressive, but thousands working in parallel unlocks true nanomanufacturing.

Reinforcement learning and AI-driven control systems

Neural networks analyze nanoscale feedback instantly

Parallel operation of thousands of molecular actuators

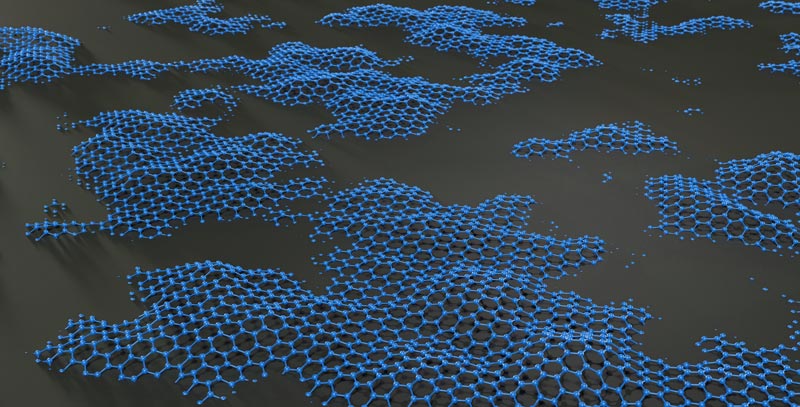

MEMS & Microelectronics

To make nanomechanical systems truly useful, they need to interface with real-world hardware—and that's where Micro-Electro-Mechanical Systems (MEMS) and microelectronics come in.

Integrating protein-based nano-actuators into traditional silicon chips

Nanoscale actuators in microelectronics

Dry, anhydrous operation outside of liquid environments

The Roadmap: How We Get There

We’re executing a phased R&D plan guided by Model-Based Systems Engineering (MBSE)—an iterative approach ensuring efficient, data-driven progress:

01

Protein “Nano-Arms” & Minimizing Friction

Single-axis actuators (2–5 nm displacement, ~10 pN force) combined into multi-axis arrays.

DNA as a guide (DNA-templated assembly): Precisely positions these protein arms, allowing mechanical amplification where needed.

Special crosslinking + “smooth” surface design reduce “sticktion” (unwanted sticking) in dry environments, ensuring stable motion.

02

Closed-Loop AI Control

Real-time drift correction at sub-nanometer accuracy—so arms remain precise.

As systems scale to multi-axis arrays, AI can reconfigure them for specialized tasks (e.g., advanced sensors, CNT (carbon nanotube) computing).

03

The Roadmap

Demonstrate single-axis and small multi-axis arrays.

Achieve microscopy-level color shift as a visible milestone.

Expand to multi-micron arrays with higher yield and uniformity.

Milestone: “Mini hero demo” visible to the naked eye.

Develop millimeter- to centimeter-scale arrays and pilot commercial spinouts.

Milestone: Real-time, color-shifting surface—an undeniable proof of large-scale molecular assembly.

What's Possible?

Our ultimate “Hero Demo”—a surface that instantly shifts color and texture—proves that nano-arms can dynamically rearrange molecules at scale. But this is just the beginning.

Join the Open Ecosystem

Meet our team